Working Principle

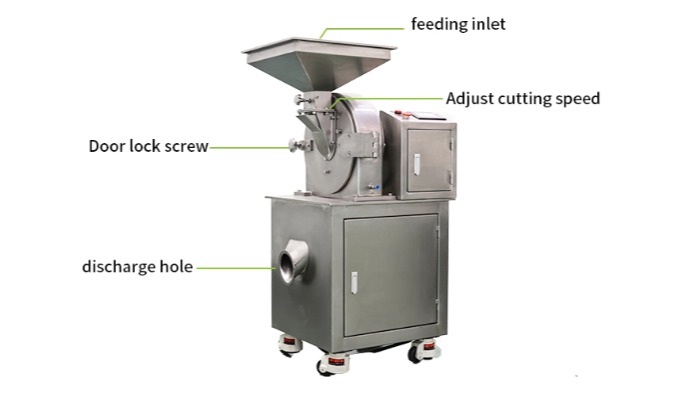

The universal crusher mainly consists of a feeding port, a crushing chamber, a rotor, a screen, a discharge port, and other parts. Among them, the crushing chamber is the main working area of the equipment, which is equipped with a rotor made of high-strength materials. The rotor rotates at high speed in the crushing chamber to impact and grind the materials, achieving the purpose of crushing. The sieve is used to control the particle size and size of the crushed material. The discharge port is used to discharge the crushed material from the equipment.

The universal crusher mainly adopts the principles of impact and grinding for crushing. When the material enters the crushing chamber, it is subjected to the impact and shear force of the high-speed rotating rotor, and the material is crushed into small pieces. Subsequently, these small pieces are gradually ground into smaller particles under the grinding action of the rotor. Finally, through the control of the sieve, materials that reach the required particle size are discharged from the equipment, while particles that do not meet the requirements continue to be crushed in the crushing chamber.

| Model | 20B | 30B | 40B | 50B | 60B | 80B |

| Handling capacity(kg/h) | 20-150 | 30-300 | 40-400 | 80-500 | 100-600 | 80-1000 |

| Main speed(r/min) | 4500 | 3800 | 3400 | 2900 | 2400 | 2200 |

| Max feeding size(mm) | <6 | <10 | <12 | <12 | <15 | <15 |

| Cruch size(Mesh) | 12-120 | 12-120 | 12-120 | 12-120 | 12-120 | 12-100 |

| Crusher Power(kw) | 4 | 5.5 | 7.5 | 11 | 22 | 37 |

Your Position:

Your Position:

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).