- HOME

- PRODUCTS

-

vibrating screen

Trommel screen

DY-450 filtering sieve

Lab sieve

Liquid vibrating separator

Scraper rotary vibrating screen

ZSG heavy vibration screen

High frequency stack sieve

Rotary vibrating screen

Circular vibrating screen

Test sieve

Ultrasonic vibrating screen

Gyratory vibrating screen

Air-flow screening machine

Dewatering screen

Tumbler separator

Discharge vibrating screen

DZSF series linear vibratory screen

Electromagnetic Sieve Shaker

Feeder equipment

Vertical vibrating elevator

Bucket elevator

Dust-free Feeder

Vacuum Feeder

Z type bucket elevator

Vibratory feeder

Hammer crusher

Jaw crusher

Roller crusher

Impact crusher

conveyor equipment

Belt conveyor

Vibration table

Vertical screw conveyor

Plated Spring Vibratory Conveyor

Tube Type Vibratory Conveyor

Screw conveyor

Grain Suction Machine

Pulverizer Grinding Equipment

Universal Crusher

Dust Collection Universal Crusher

Wood Grinder

Packaging Equipment

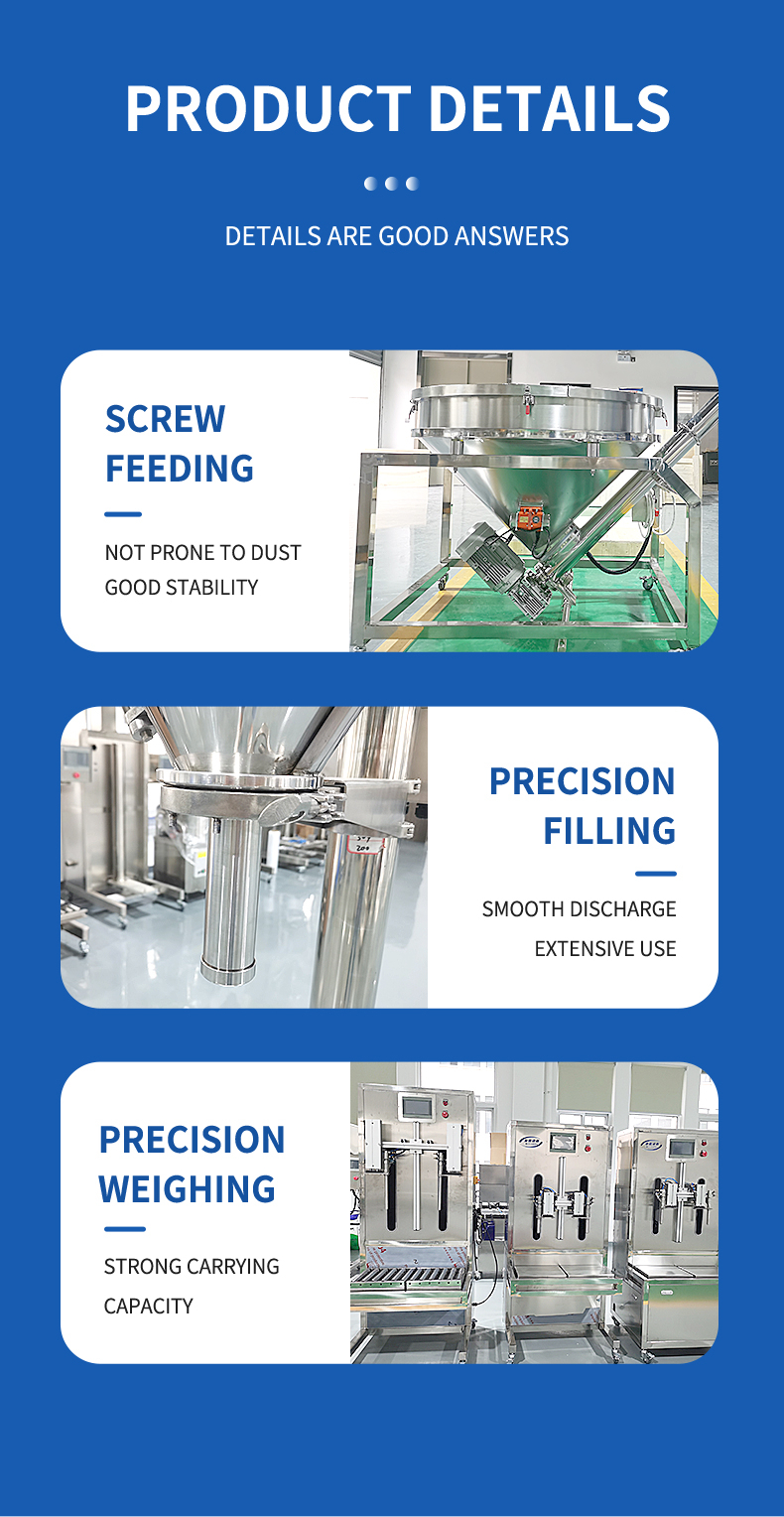

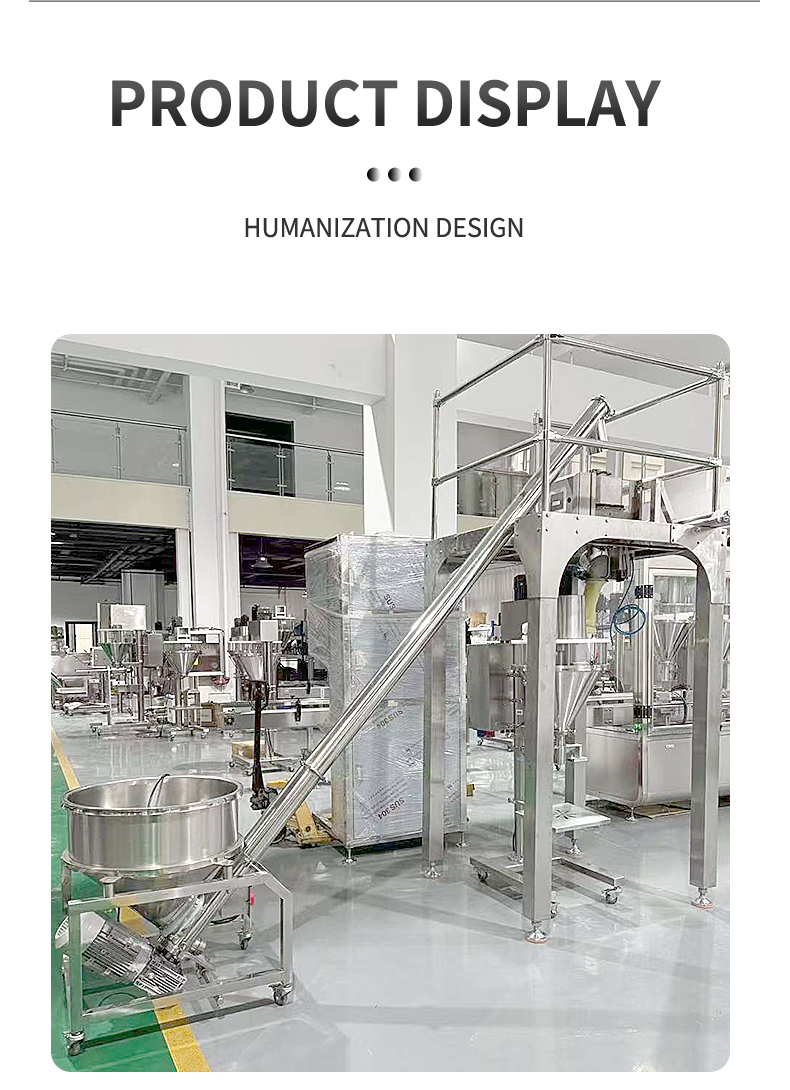

Powder Filling Machine

Mixing Equipment

Electric heating mixer

-

- COMPANY PROFILE

- CASE

- FAQ

- NEWS

- APPLICATION

- CONTACTS

Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 laura@vibratingscreen.cc

laura@vibratingscreen.cc +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).