-

How to increase the output of vibrating screens?

How to increase the output of vibrating screens?

How to increase the output of vibrating screens? Xinxiang Dayong Machinery will answer your questions.

-

.jpg) What should be noted when using a stainless steel vibrating screen?

What should be noted when using a stainless steel vibrating screen?

When using a stainless steel vibrating screen, the following six points should be noted.

-

.jpg) What are the factors that affect screening efficiency?

What are the factors that affect screening efficiency?

Factors affecting screening efficiency: material characteristics, selection of screening surface, production conditions.

-

.jpg) How to improve the screening efficiency of vibrating screens?

How to improve the screening efficiency of vibrating screens?

Vibration screen is a common screening equipment widely used in various fields. The output of vibrating screens is closely related to many factors. Xinxiang Dayong Machinery will introduce to you today the method of increasing production through screening efficiency.

-

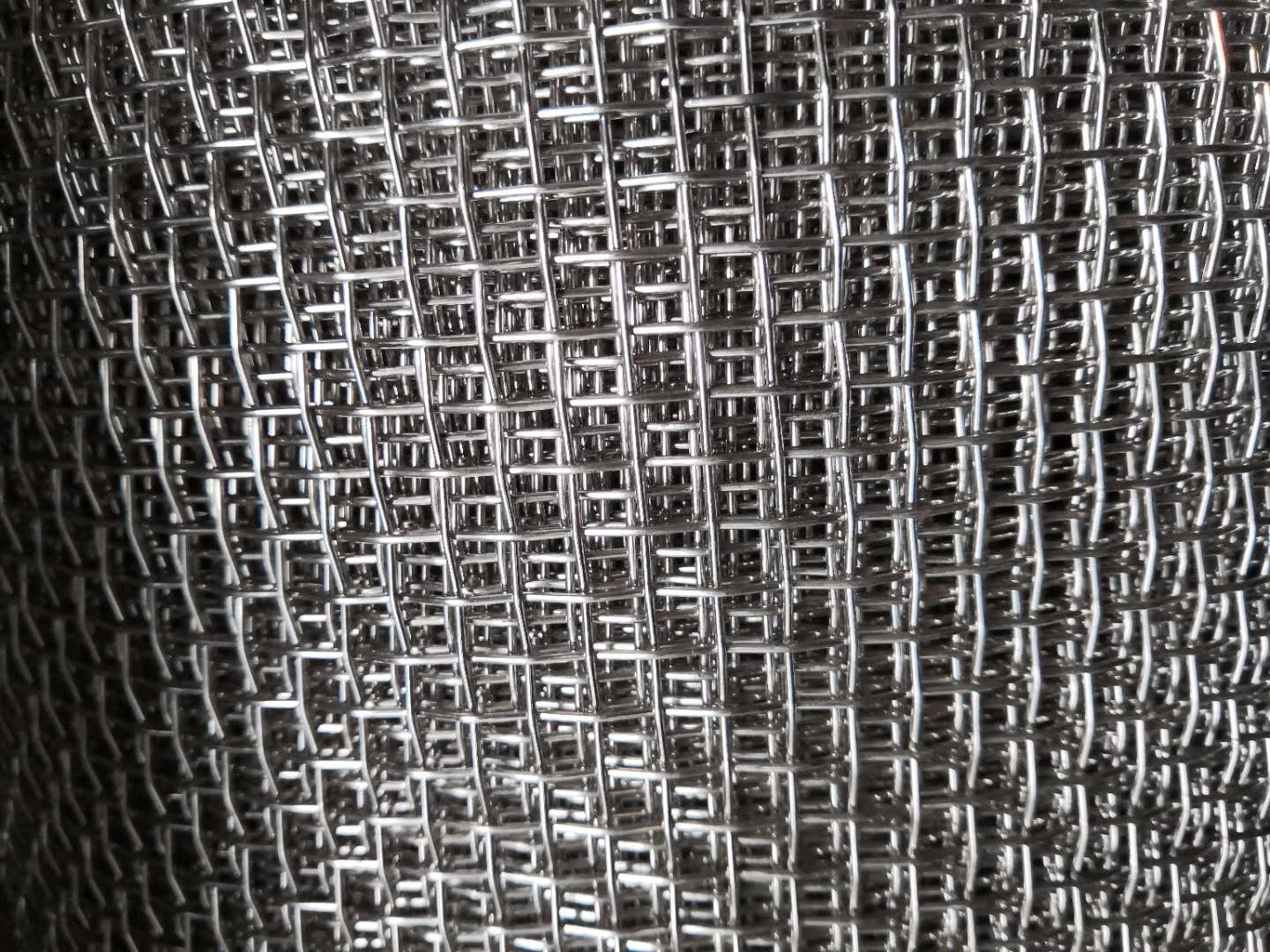

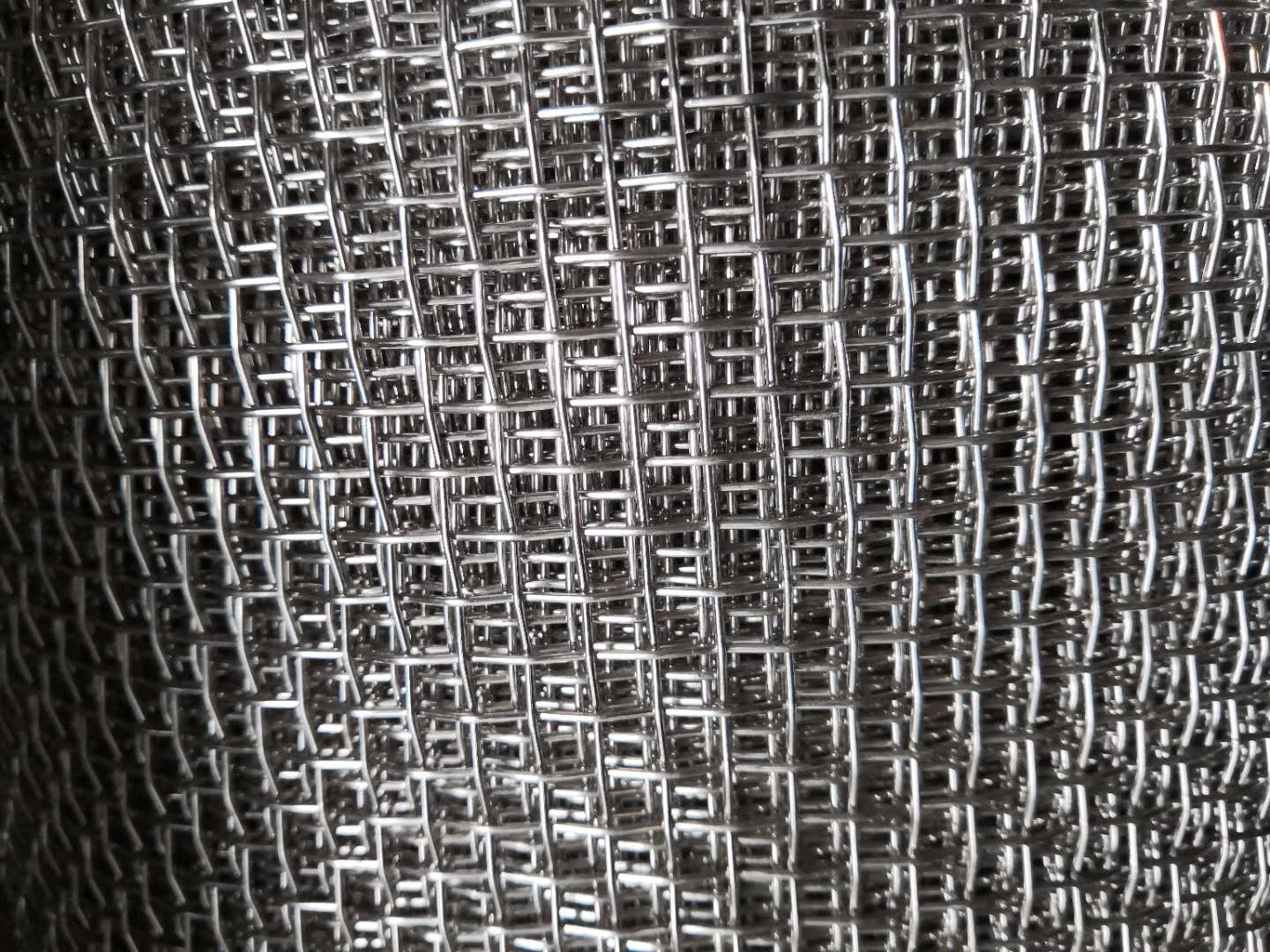

How long does the lifespan of the vibrating screen mesh last?

How long does the lifespan of the vibrating screen mesh last?

The lifespan of a sieve is also related to many factors, such as the condition of the material, the size of the sieve, and the quality of the sieve.

-

.jpg) What are the advantages of the gyratory vibrating screen

What are the advantages of the gyratory vibrating screen

What are the advantages of gyratory vibrating screen? Xinxiang Dayong Machinery will introduce them to you.

-

Why use a round swing screen when sifting flour?

Why use a round swing screen when sifting flour?

There are many reasons to use a circular swing sieve to screen flour. Xinxiang Dayong Machinery will provide you with a detailed explanation.

-

How to choose different shapes of screw conveyors?

How to choose different shapes of screw conveyors?

Spiral conveyors come in many different shapes.Xinxiang Dayong Vibration Equipment Co., Ltd. will take you to analyze the advantages and disadvantages of different screw conveyors.

-

What is the difference between a circular vibrating screen and a regular vibrating screen?

What is the difference between a circular vibrating screen and a regular vibrating screen?

The difference between a circular vibrating screen and a regular vibrating screen,and how to choose.Xinxiang Dayong Vibration Equipment Co., Ltd. will introduce you from four aspects.

-

.jpg) How to choose a suitable vibrating screen?

How to choose a suitable vibrating screen?

Faced with numerous types of vibrating screens, many customers do not know how to choose. This article will analyze how to choose a vibrating screen from three perspectives. I hope it can help you.

-

How to reduce the wear and tear of linear vibrating screen?

How to reduce the wear and tear of linear vibrating screen?

Linear vibrating screen is a widely used equipment, which is used in the quarry, chemical, food, pharmaceutical industries.Linear vibrating screen utilizes vibrating motor excitation as the source of electricity, so that the material is thrown up on the screen mesh, and at the same time, it moves forward in a straight line.This kind of movement will bring wear and tear to the machine, Dazhong Machinery will explain to you how to care and maintain the linear vibrating screen.

-

.jpg) Why does the vacuum conveyor not convey materials anymore? What are the reasons?

Why does the vacuum conveyor not convey materials anymore? What are the reasons?

Vacuum conveyor are widely used in a variety of industries for conveying powder particles,There are more and more factories that use vacuum loaders to convey materials.But in the feeding process will inevitably encounter some can not work properly, the common is the feeding machine does not feed or suction slow, so what is the reason? Dazhong machinery for you to analyze.

-

How to sieve flour through the low-profile sifter

How to sieve flour through the low-profile sifter

low-profile sifter is a screening equipment for particle screening and separation.The core principle is that a single horizontal vibration motor is the excitation source, and after the material enters the equipment, it is subjected to the excitation force on the screen surface and makes an elliptical motion trajectory,So as to realize the screening of materials.The low-profile sifter can screen all kinds of powder particles, such as flour, powdered sugar, milk powder, etc.

-

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

-

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

-

.jpg) Frequently Asked Questions about Rotary Vibrating Screens

Frequently Asked Questions about Rotary Vibrating Screens

Frequently Asked Questions about Rotary Vibrating Screens

-

What should I do if the screen mesh of the rotary vibrating screen is blocked?

What should I do if the screen mesh of the rotary vibrating screen is blocked?

What should I do if the screen mesh of the rotary vibrating screen is blocked?

-

Operation steps of rotary vibrating screen in screening Chinese herbal medicines

Operation steps of rotary vibrating screen in screening Chinese herbal medicines

Operation steps of rotary vibrating screen in screening Chinese herbal medicines

-

.jpg) What are the requirements when selecting ultrasonic vibrating screens?

What are the requirements when selecting ultrasonic vibrating screens?

Based on 14 years of experience, we have summarized the following information and summarized the 4 main points for purchasing screens. Let’s take a look at them together:

-

.jpg) Which sifting machine is best for sifting flour?

Which sifting machine is best for sifting flour?

Screening machine is the general term for all vibrating screening machines. There are many categories, such as linear vibrating screen, three-dimensional vibrating screen, drum screen, swing screen, air flow screen and other different screening machines.

-

What industries are vacuum conveyors suitable for?

What industries are vacuum conveyors suitable for?

What industries are vacuum conveyors suitable for?

-

What should we pay attention to when operating a screw conveyor safely?

What should we pay attention to when operating a screw conveyor safely?

Xinxiang Dayong Vibration Equipment Co., Ltd., we produce high-efficiency rotary vibrating sieves, linear vibrating sieves, liquid sieving filters, circular swinging sieves. We produce screw conveyors, belt conveyors, vacuum feeders, bucket elevators, etc. We can provide screening conveyor machinery production lines.

-

Routine maintenance of screw conveyor

Routine maintenance of screw conveyor

Routine maintenance of screw conveyor

-

.jpg) The Structure of Screw Conveyor

The Structure of Screw Conveyor

The Structure of Screw Conveyor

-

.jpg) How often should the screen and screen frame be cleaned?

How often should the screen and screen frame be cleaned?

The frequency of cleaning the screen and screen frame will vary on a case-by-case basis and depends on the following factors:

(Live chat)

(Live chat)

_213x160.jpg)

+86-373-3669005

+86-373-3669005 sale@dyvibratingscreen.com

sale@dyvibratingscreen.com +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)